All you need to know about climbing ropes!

We'll take a look at..:

- The different types of rope

- Technical data

- Coatings

- Which rope for which activity?

- How to maintain your rope

- What is a climbing rope like?

A rope is made up of two parts: the sheath (often colored), made of woven synthetic fibers, and the core (white), made of braided fibers. The threads are made of polyamide for greater durability and rot-proofing.

- The different types of rope

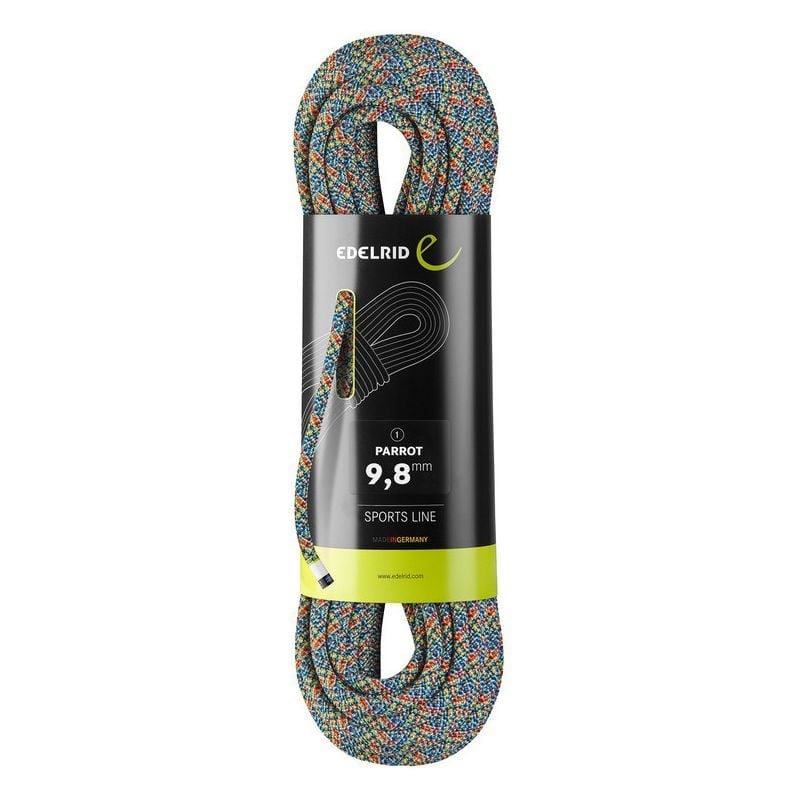

Dynamic ropes:

|

Single ropes: The sport par excellence!

Recognized by the ![]() symbol, this rope is used for climbing several pitches (known as "long routes"). The double rope allows you to climb two strands of different colors, and "abseil" down the same pitches as those climbed. Much thinner and lighter, it has a diameter of between 8 and 9 mm and weighs between 40 and 50 g/m per strand. This type of rope also allows you to limit the pull on the ascent, as the two strands are clipped alternately to the quickdraws, making it possible to belay two rope mates.

symbol, this rope is used for climbing several pitches (known as "long routes"). The double rope allows you to climb two strands of different colors, and "abseil" down the same pitches as those climbed. Much thinner and lighter, it has a diameter of between 8 and 9 mm and weighs between 40 and 50 g/m per strand. This type of rope also allows you to limit the pull on the ascent, as the two strands are clipped alternately to the quickdraws, making it possible to belay two rope mates.

Semi-static and static ropes:

|

This type of rope is not suitable for climbing. As the name suggests, they have no elasticity, so to avoid hip fractures, no climbing with semi-static or static ropes!

Some disciplines, such as caving, canyoning or working at height on ropes, require rigidity to avoid the yo-yo effect (when abseiling or ascending on ropes).

Recognizable by its white color, its elasticity is between 2 and 5% (in comparison, a dynamic rope is around 28-35%).

|

|

- Technical data

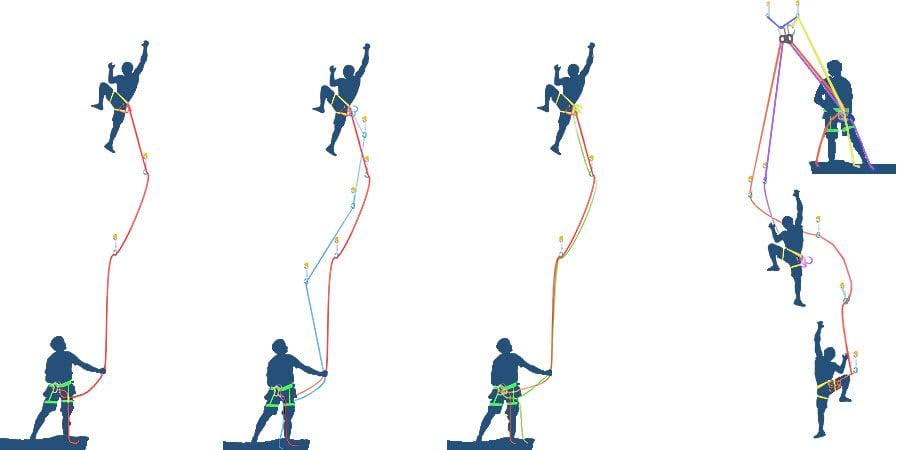

Fall factor

The fall factor corresponds to the length of fall in relation to the length of rope available. In climbing, the hardness of a fall does not depend on height, since the longer the rope, the greater its absorption capacity.

|

In both cases, the fall height is identical, but depending on the length of rope available, it will be more severe in case 2, because the rope's absorption capacity is lower than in case 1.

Impact force

The elements taken into account to calculate the impact force are:

- m is the climber's mass in kg,

- G is the acceleration of gravity = 9.81m/s,

- h is the height of the fall in meters,

- v is the speed in m/s.

This gives us the following formula: Impact force = Mg (1+√(1+2Ks/Mg fc))

- The climber's body, which also absorbs energy

- The harness

- The roping knot

- belay points

- Rope friction

- The actual fall factor...

|

Standard 892

Please note that, depending on the activity, the type of rope is not the same and the maximum shock force authorized by the standard is different.

- Single strand: 5 falls,

- Double strings: 5 falls,

- Twin strings: 12 falls.

- Rope treatments

|

Sheath wire treatment before manufacture |

|

Increases the rope's resistance to friction and dust. Rope absorbs less than 15% moisture |

|

Hydrophobic chemical treatment of core wire and sheath before manufacture. |

|

Waterproofs core and sheath threads by polymerization, making the rope more durable against water and dirt. Will not freeze and absorbs less than 3% of moisture. Meets UIAA WATER REPELLENT standard. |

-

Petzl: UltraSonic Finish: the core and sheath are joined at their ends, thanks to an ultrasonic finish called UltraSonic Finish.

-

Tendon: Patented TeFIX® technology permanently binds the sheath to the core.

-

Beal: Unicore® technology

|

- Which rope for which practice?

|

Indoor climbing |

|

TENDON MASTER 9.7 STANDARD MAMMUT 9.8 CRAG CLASSIC ROPE |

|

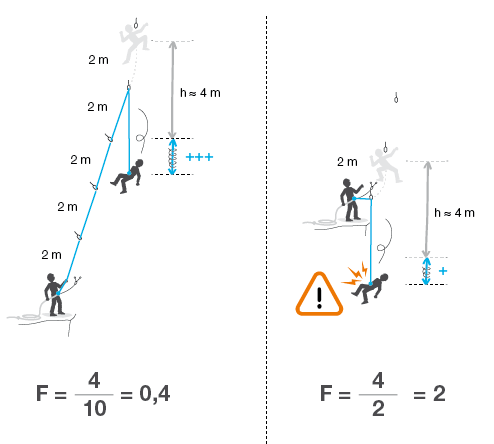

Sport climbing |

|

EDELRID PARROT 9.8MM PETZL CONTACT 9.8 MM TENDO MASTER PRO 9.7 |

|

Long routes and mixed mountaineering |

|

AMBITION 7.9 ALPINE PETZL RUMBA 8MM TENDON |

|

Ice climbing |

|

PETZL PASO GUIDE 7.7 MM EDELRID SWIFT 48 PRO DRY 8,9MM |

|

Hiking, via ferrata, glacier roping |

|

MAMMUT 9.5 CRAG DRY ROPE EDELRID SWIFT 48 PRO DRY 8,9MM |

|

- How to care for your rope

Check your rope:

Storage :

|

The lifespan of a climbing rope varies according to the manufacturer, but averages around 10 years. Obviously, this figure should be treated with caution, as nothing beats a visual inspection of the rope. Moreover, this value decreases with the number of falls the rope undergoes during use.

_1.jpg)